Keel Design According to Perry (Guest Post by Bob Perry)

"Go ahead and love your crab crusher full keel boat but don’t try to justify the design on technical terms. Some traditional full keel designs have a lot of subjective, aesthetic appeal. That’s good enough reason to love your boat."

-Bob Perry (see below)

I share a lot of my own sailing-related experiences and ponderings here on my blog, but occasionally I have the opportunity to share the perspective and experiences of some real experts. Today I'm pleased to welcome Bob Perry back as a guest blogger [Read Bob's prior contributions to SailFarLiveFree about double-enders and sailboat rigs]. It seems keels are often debated on sailing blogs and forums, so rather than rehash those stale discussions, I asked Bob if he'd share his unique design perspective on the diversity of keel types available for cruisers. Graciously, he obliged. What follows is a guest blog post and photos Bob provided to me.

Keel Design According to Perry, by Bob Perry

"Let’s talk about keels. That is always sure to get someone’s knickers in a twist. I’ll sort of just ramble along. We can start with what a keel has to do. It has to provide a location for the vessel’s ballast. It has to balance the forces of the rig. It has to provide lift to insure weatherly performance. And, if we are talking about a cruising boat, it’s nice if the keel can support the weight of the boat when hauled out. This is not necessary but it is convenient. Clearly these requirements for the keel are not all in harmony with each other. The best shape for balancing the rig may not be the best shape for ballast location. When you add in draft considerations due to area of operation, keel design can involve a lot of compromise with pragmatic issues overwhelming pure foil design technical issues. If we are talking about a mass produced grp (glass-reinforced plastic) boat that comes out of a female mold, mold considerations may also play a major part in determining the shape of the keel. There are some shapes you just can’t pull out of a mold.

|

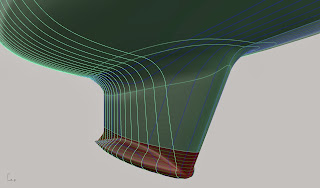

| This is the keel of a 62' ketch Pacific Seacraft is building showing a pronounced bulb. |

Face it - The most effective keel to drive the boat to weather and provide minimal drag off the wind is a high aspect ratio, deep, short chord (fore and aft dimension of the fin) T bulb keel. There is no mystery around this. Look at all the modern, high performance racing boats. T keels dominate with a long skinny bulb hanging on a dagger like fin. This is efficiency. But it requires a kelp cutter because that T configuration will pick up kelp all day long and a small amount of kelp wrapped around the keel can kill performance. For most of us cruisers a T keel is simply not practical. So we have to compromise.

The biggest area of compromise will be draft. I live on Puget Sound so draft is not a problem for me. I could own a boat with 10’ draft and it would have little effect on where I go or where I anchor. I’m lucky. Most people consider anything over 6’ draft to be deep. Not sure why but it seems that way. So if we have a hypothetical 40’ boat, 6’ draft would be typical for the cruiser. I’d prefer 7’ of draft as a designer but I can work with 6’. Now how much fin do I need? I know some of you cling to the idea that “full keels” are the way to go. But you should be careful lumping all full keel designs in together. There are good full keel boats and there are bad full keel boats. The keel is just one component of the design.

I have designed a series of full keel boats (Baba 30, Baba 35, Baba 40, Tashiba 31, Tashiba 36) and all of these boats sail quite well. But I have pulled the leading edge of the “full” keel aft and tried to give it a reasonable leading edge in terms of shape. Some people call these designs “modified full keels”. That’s OK but those labels can be pretty nebulous. Probably my biggest complaint with full keel designs is that they seldom if ever back up well under power. They also add a lot of wetted surface and that can kill light air performance. Plus, they are so long in chord that if you give them a good efficient foil say with a thickness ratio of 10% (width of the keel compared to the chord length) you will end up with a fat keel that adds too much displacement to the boat. And the funny thing is, and it’s not intuitive, all that keel volume is on the wrong side of the righting arm when the boat heels over. So technically a big full keel can reduce your righting moment. Go ahead and love your crab crusher full keel boat but don’t try to justify the design on technical terms. Some traditional full keel designs have a lot of subjective, aesthetic appeal. That’s good enough reason to love your boat.

|

| This is a view down into the keel "envelope" or fin of the 62' Pacific Seacraft boat showing the way the floors and longitudinals are used to support the keel area. |

I have designed a series of full keel boats (Baba 30, Baba 35, Baba 40, Tashiba 31, Tashiba 36) and all of these boats sail quite well. But I have pulled the leading edge of the “full” keel aft and tried to give it a reasonable leading edge in terms of shape. Some people call these designs “modified full keels”. That’s OK but those labels can be pretty nebulous. Probably my biggest complaint with full keel designs is that they seldom if ever back up well under power. They also add a lot of wetted surface and that can kill light air performance. Plus, they are so long in chord that if you give them a good efficient foil say with a thickness ratio of 10% (width of the keel compared to the chord length) you will end up with a fat keel that adds too much displacement to the boat. And the funny thing is, and it’s not intuitive, all that keel volume is on the wrong side of the righting arm when the boat heels over. So technically a big full keel can reduce your righting moment. Go ahead and love your crab crusher full keel boat but don’t try to justify the design on technical terms. Some traditional full keel designs have a lot of subjective, aesthetic appeal. That’s good enough reason to love your boat.

As I mentioned, the first thing to be decided with a new keel is draft. With draft chosen the size and geometry of the fin can be addressed. If the boat has outside ballast, lead, then the designer has some latitude in how the fin will be shaped. The lead ballast will come out of its own mold and can be bulb configured to help get the VCG (vetical center of gravity) as low as possible. If the ballast is internal (some people call this “encapsulated”) then the keel fin is part of the molded hull and must be designed so it can be pulled from a mold. If it is a one piece mold this can put a lot of restrictions on the keel shape. People go back and forth over the pros and cons of internal vs. external ballast. I like external due to the design freedom it gives me. I also like a big chunk of lead on the bottom of my boat when I hit rocks. But internal ballast, lead or iron, can work just fine and you don’t have to be concerned about keel bolts. But you will have a fatter keel with more frontal area with an internally ballasted boat, especially if it is internal iron ballast. Lead is 700 lbs. per cubic foot while iron is 450 lbs. per cubic foot.

The keel for my radical 62’ by 9’10” beam FRANCIS LEE draws 10’. The client did not want a T fin so we went with an “L” fin so that it would be less prone to catching kelp. This high aspect ratio keel has a cast lead bulb bolted onto a welded steel hollow fin with a massive plate at the hull. It is bolted through the hull and through an extensive s.s. grid system that spreads the loads out to the structure and keeps the loads off the shell. With such a long and skinny boat I needed the ballast to be as low as possible to provide adequate stability.

|

| The client's son Derek either contemplating the fairing of the big L configuration keel or picking his nose. |

On more mainstream designs like my other 62’er currently being finished, CATARI, I have restricted draft at 7’. The fin is a low aspect ratio fin with a 1-% thickness ratio and a beaver tailed bulb at the tip. I have a very similar keel on a new 45’ double ender I am doing for a Swedish client. It’s a relatively low aspect ratio fin with a bulb tip and a small beaver tail. The beaver tail is intended to smooth out the tip vortex of the fin and reduce drag.

|

| This is the keel of the 45' Swedish client's showing a subtle bulb at the tip. |

We don’t have to guess anymore about keels and draft. I use a Velocity Prediction Program (VPP) to analyze my hulls and keels. I can try various keels and drafts and pick the one that gives me the best combination of performance results. We reduced the draft on CATTARI 6” after doing a series of VPP runs." -BP

So, did you learn something new about keel design? If so, thank Bob. If not, blame me! Seriously, thanks to Bob for the lesson in keel design.

Looking for more information about cruising boat design? Try these resources (including previous SFLF posts):

- Yacht Design According to Perry (Book by Bob Perry)

- Double Enders According to Perry (Guest Blog Post by Bob Perry)

- Sailboat Rigs According to Perry (Guest Blog Post by Bob Perry)

- 50 Years of Cruising Sailboat Evolution (Guest Blog Post by Ted Brewer)

- The Metal Yacht - Aluminum & Steel Sailboat Perspectives (Guest Post by Ted Brewer)

- Understanding Boat Design (Book by Ted Brewer)

Great topic, well handled.. thanks to you both!

ReplyDeletefor a modifided full keel, Scheel Keel. Pure logic, no designer would pay royalties and use it, if it did not work! Bud.

ReplyDeleteI hate keels for a million reasons the main one being draft but they also have a low center of effort you want that higher at the same level as the sail center of effort no heeling moment. This is not possible but up is the way to go so what is the answer? Leeboards my favoured boat at the moment is the dutch lemsteraak for a lot of reasons. I wish boat designers would do a modern take on this vessel (hint).

ReplyDelete